Manufacturing Engineering

Studies on high efficiency, high precision, high quality, optimization, and intelligent automation of machining, which is the basic technology of manufacturing, and its peripheral technologies are carried out. In particular, advanced manufacturing technology for both machine tool users and builders is being developed through studies on not only grinding, cutting and abrasive finishing or their evaluation technology, but also further development of AI / IoT technology specialized in the field of manufacturing.

|

|

|---|---|

|

|

|

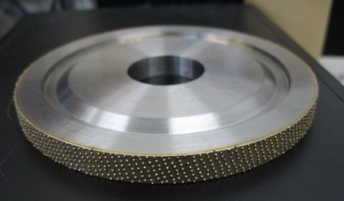

Applying fine abrasive grains to the surface of the material by the kinetic energy of tools and fluids removes materials below the micron level. A machining technology, that creates a fine shape on the surface with a required surface function, and a method for evaluating its surface properties have been developed by controlling the action of these abrasive grains.

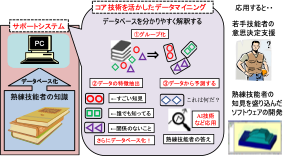

We are developing a sustainable decision support system for skilled workers by applying AI techniques to data mining technology, which enables feature extraction and trend visualization from databases of all kinds of databases in the manufacturing field, such as cutting, grinding, and polishing processes.

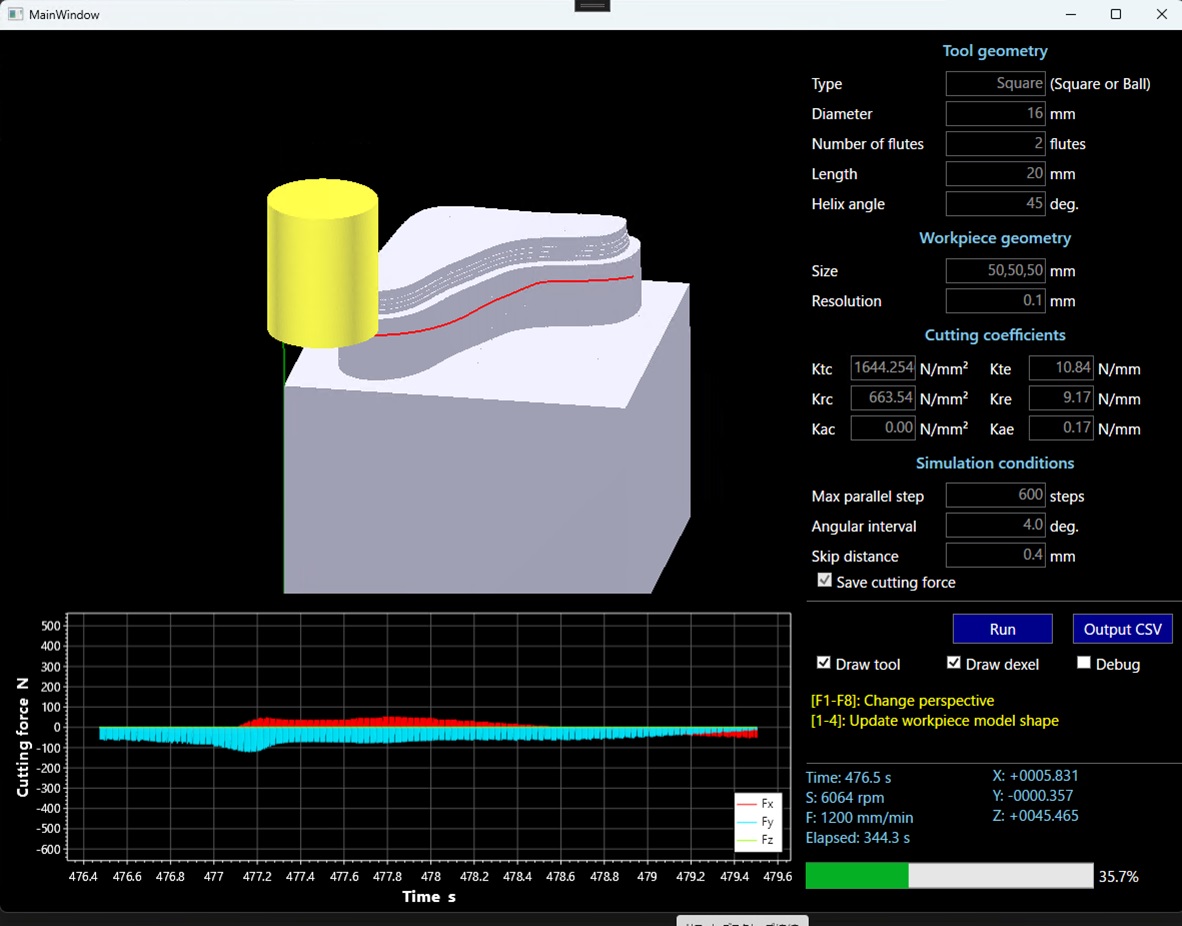

We are developping a simulator to predict cutting forces and machining accuracy in cutting operations. It is also working on digital twin technology that links our simulator and machine tools to virtually monitor machining state.