Nontraditional Machining

Along with the rapid progress of industrial technology, various new materials with excellent properties have been developed. Most of these materials are difficult to machine by the conventional mechanical methods, and the demand for machining of fine complicated shapes has been increased. Our laboratory is researching on high-performance and high-functional nontraditional machining methods, such as Electron Discharge Machining (EDM), Electron Beam Machining (EBM), and Laser Beam Machining (LBM) with using electric, electronic, optical energies. In addition, we are developing novel machining methods for the next generation.

|

|

|---|

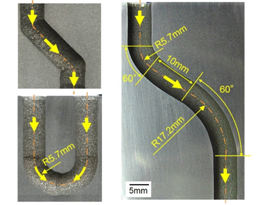

1.Study on High-performance Electrical Discharge Machining

Spark distribution, debris movement, wire deflection and vibration during electrical discharge machining (EDM) process are clarified by high-speed observation and by simulations including computer fluid dynamics and structural analysis. Based on these results, improvement in EDM characteristics are discussed for high-performance EDM technology. In addition, novel EDM applications, such as curved-hole EDM drilling, multi-EDM slicing of silicon and silicon carbide, and surface functionalization by EDM are studied.

|

|

|---|

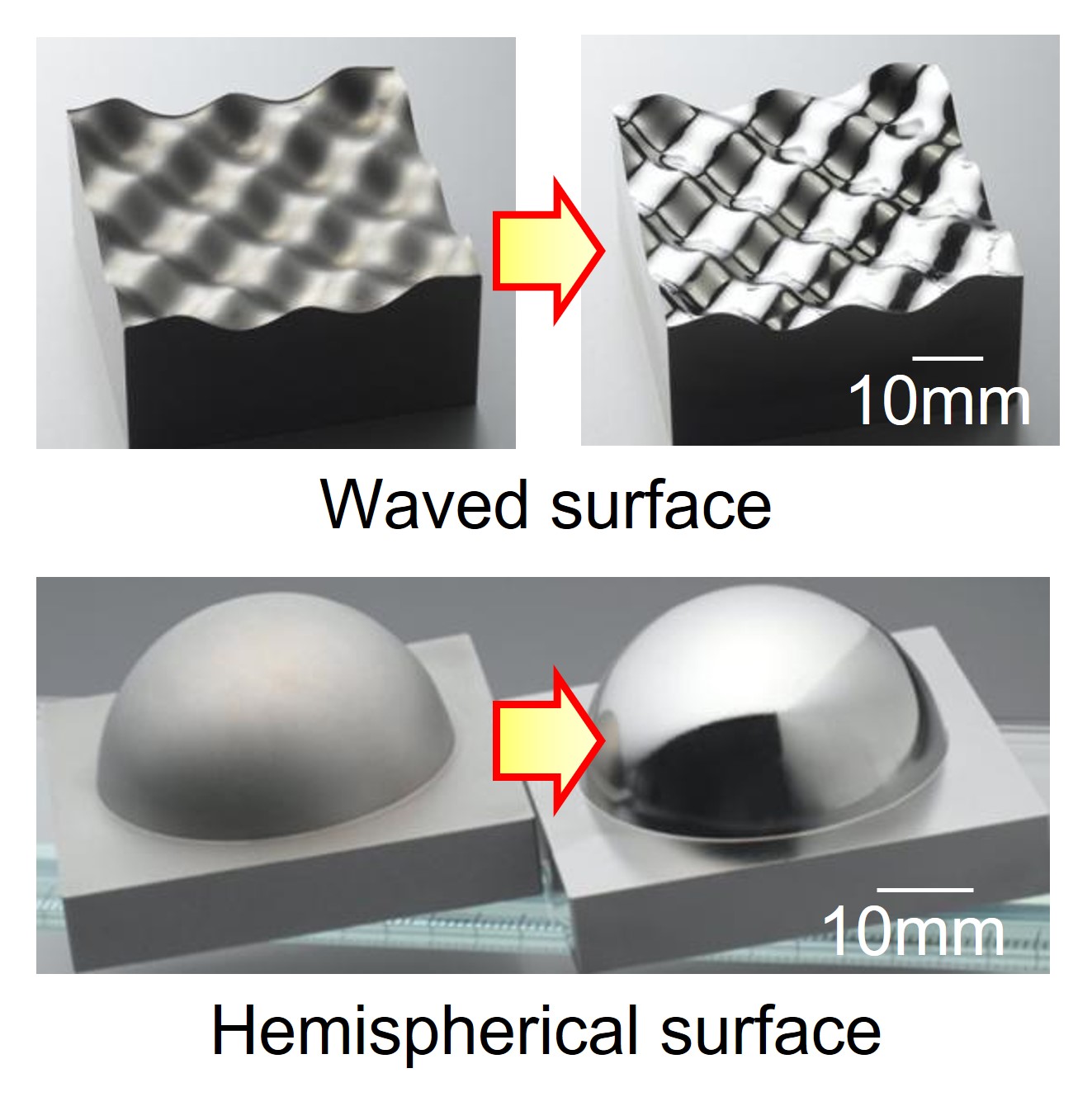

3.Highly Efficient Surface Finishing and Modification of Metal Surface by Large-area EB Irradiation area EB Irradiation

New large-area EB irradiation method with a 60mm in diameter was recently developed by our research group. Wide area of metal surface can be melted instantly and uniformly by using this method, and highly efficient surface finishing for metal products such as metal mold and implant can be performed. Furthermore, surface characteristics such as water repellency and corrosion resistance can be also improved.